ELECTROLYTIC REFINING OF GOLD

The electrolytic refining technique allows to yield high purity gold 999.9/1000.

Our systems are designed and manufactured to run the process efficiently and safely.

The process efficiently works when the input material is minimum 980/1000.

The ouput of the electrolytic refining process is pure gold 999.9/1000.

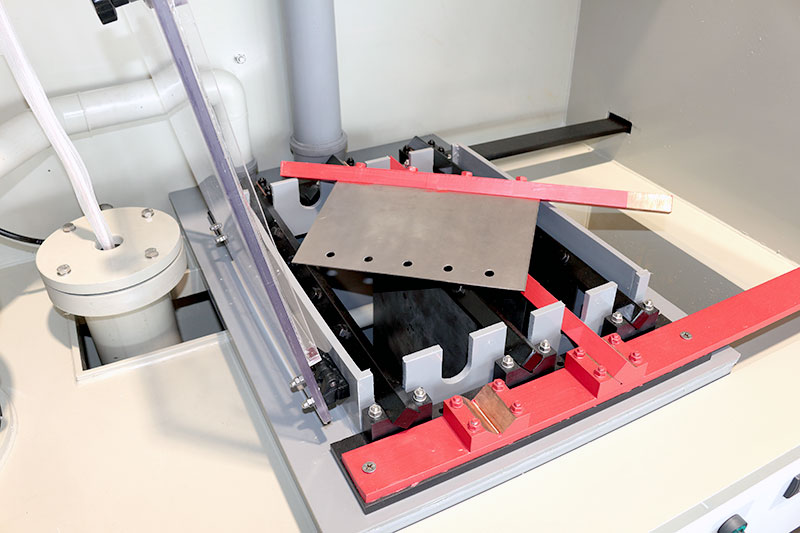

The gold electrolytic refining plants are built inside polypropylene fume hoods and, thanks to the polypropylene modularity, are able to cover a wide range of production requirements.

MAIN FEATURES:

- Modular systems made of electrolytic cells of 05 / 10 / 15 kg capacitity (as output material per day)

- 24h operational cycles – no supervision required

- Very limited maintenance required

- User-friendly apparatus

- Possibility to recover PMs as by product (anodic sludges)

- Combo plants available with electrolytic cell and reactor for the preparation of the electrolyte solution (AuCl3)

|

|

|

|

| Model | BT-ELTR-AU-005 | BT-ELTR-AU-010 | BT-ELTR-AU-015 |

| 24h output Au 999.9/1000 [kg] | Max 05 | Max 10 | Max 15 |

| Electrolytic cell volume | 25L | 50L | 60L |

| Input capacity | Min 3 kg Max 9 kg |

Min 3 kg Max 18 kg |

Min 3 kg Max 27 kg |

| Power supply | 380 V – 50 Hz – 3ph * | ||

| Power | 2 kW ** | 4 kW ** | |

| Dimensions [mm] LxPxH | 1.200 x 800 x 2.000 | 1.500 x 800 x 2.000 | 1.500 x 1.000 x 2.000 |

* depending on the installation country electrical specs

** depending on the configuration / devices installed

Interested? Contact us for info.

Balestri Technologies S.r.l.

Balestri Technologies S.r.l.